- Home

-

-

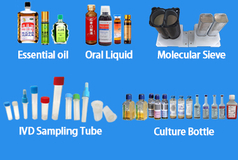

- Xilin bottle liquid vial filling machine vial machine, plugging and capping vial sealing machine

- Wind oil essence, activating oil, perfume small liquid filling machine filling line equipment

- filling roller bottle cold compress gel high speed filling machine

- Rhinitis nasal Spray bottle filling machine

-

-

- PET bottle juice filling machine juice bottling machine juice filling line

- Juice beverage filling machine capping packaging machine production line

- Oral liquid filling machine gas washing bottle filling line

- Pulp milk beverage bottle cleaning bottle high speed rotary fruit juice filling packing machine

-

-

- Dishwashing paste hot filling and cold pressing capping production line

- Perfume filling machine prices high speed plug capping production line

- Automatic bottling balm filling machine price and cooling small bottle filling machine

- Medicated disinfectant toner perfume spray digital liquid filling machine price bottling machine

-

-

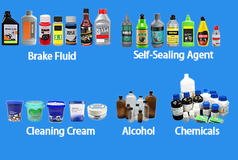

- Tire self-hydrating industrial bottle filling machine liquid filler

- Detergent Corrosion-resistant liquid filling machine industrial bottle filler

- Sterilization gel filling machine explosion-proof pharmaceutical liquid filling machine

- automatic 16 head ink filling cap screwing aluminum foil sealer ink filling machine

-

High-speed Bottle Washing, Filling, Capping And Labeling Production Line

Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

High-speed bottle washing, filling, capping and labeling production line

Through ultrasonic vibration and spraying double cleaning, effectively removing internal and external impurities and dust, followed by high-temperature tunnel to complete the drying and aseptic treatment,

adopts the plunger pump filling system, to achieve the accurate filling of the material,

automatic capping and screwing, sealing, effectively preventing leakage and pollution.

After filling, the bottles are sterilized in water bath, and after sterilization, the bottles are blown dry by high-speed airflow, which is convenient for labeling and packaging.

The system has built-in visual inspection device to realize automatic inspection and labeling.

The whole line is efficiently linked, from bottle washing to labeling in one go, suitable for the production of liquid oral dosage forms for pharmaceuticals, health products and so on.