- Home

-

-

- Xilin bottle liquid vial filling machine vial machine, plugging and capping vial sealing machine

- Wind oil essence, activating oil, perfume small liquid filling machine filling line equipment

- filling roller bottle cold compress gel high speed filling machine

- Rhinitis nasal Spray bottle filling machine

-

-

- PET bottle juice filling machine juice bottling machine juice filling line

- Juice beverage filling machine capping packaging machine production line

- Oral liquid filling machine gas washing bottle filling line

- Pulp milk beverage bottle cleaning bottle high speed rotary fruit juice filling packing machine

-

-

- Dishwashing paste hot filling and cold pressing capping production line

- Perfume filling machine prices high speed plug capping production line

- Automatic bottling balm filling machine price and cooling small bottle filling machine

- Medicated disinfectant toner perfume spray digital liquid filling machine price bottling machine

-

-

- Tire self-hydrating industrial bottle filling machine liquid filler

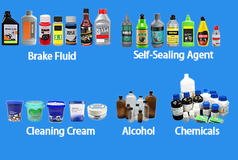

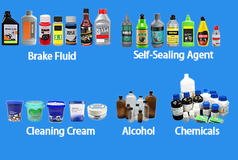

- Detergent Corrosion-resistant liquid filling machine industrial bottle filler

- Sterilization gel filling machine explosion-proof pharmaceutical liquid filling machine

- automatic 16 head ink filling cap screwing aluminum foil sealer ink filling machine

-

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Category

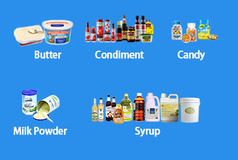

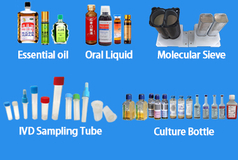

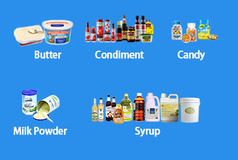

- Food machinery

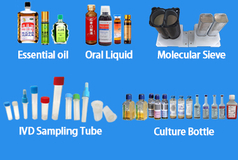

- Medical machinery

- Cosmetic machinery

- Chemical machinery

- Beverage machinery

- Filling production line series

- Filling machine series

- Capping machine series

- Sealing machine series

- Label machine series

- Bottle unscrambler, bottle washing series

- Packing machine series

- Sachet packing machine series

- Accessories/Match machinery

News

- Wet Bottle Washing, Filling And Capping Production Line

Integrates automatic bottle washing, filling and capping.Bulk bottles are arranged in order and transported to each station through the automatic bottle sorting device.Multi-station spray bottle washing is used to rinse the bottle mouth, bottle body and bottle bottom in all directions.After washing,

- Body Lotion Glycerin Water All-In-One Automatic Rotary Filling Capping Machine

Integrates filling, capping and capping in one machine.Designed for high-viscosity liquids such as glycerin.Adopts high-precision metering system to ensure accurate filling and no dripping.The equipment automatically completes operations such as capping, capping and capping.Ensures reliable sealing,

- High-speed Bottle Washing, Filling, Capping And Labeling Production Line

High-speed bottle washing, filling, capping and labeling production line Through ultrasonic vibration and spraying double cleaning, effectively removing internal and external impurities and dust, followed by high-temperature tunnel to complete the drying and aseptic treatment, adopts the plunger pum

- Dishwashing Cream Hot Filling, Cooling, Pressing And Packing Production Line

Adopting precise temperature control system to ensure smooth and even filling without collapsing.Efficient cooling and plug-pressing linkage system ensures the paste to be quickly characterized without deformation.Automatic carton loading saves time and labor, realizing the whole process automation

- Cooling oil Filling And Capping Integrated Machine

Capable of achieving continuous filling and capping operations. Without the need for frequent manual interventionReduces downtime in production. While possessing a high operating speed. Can complete the filling and capping of a large number of products in a short period of timeMeets the demands of rapid

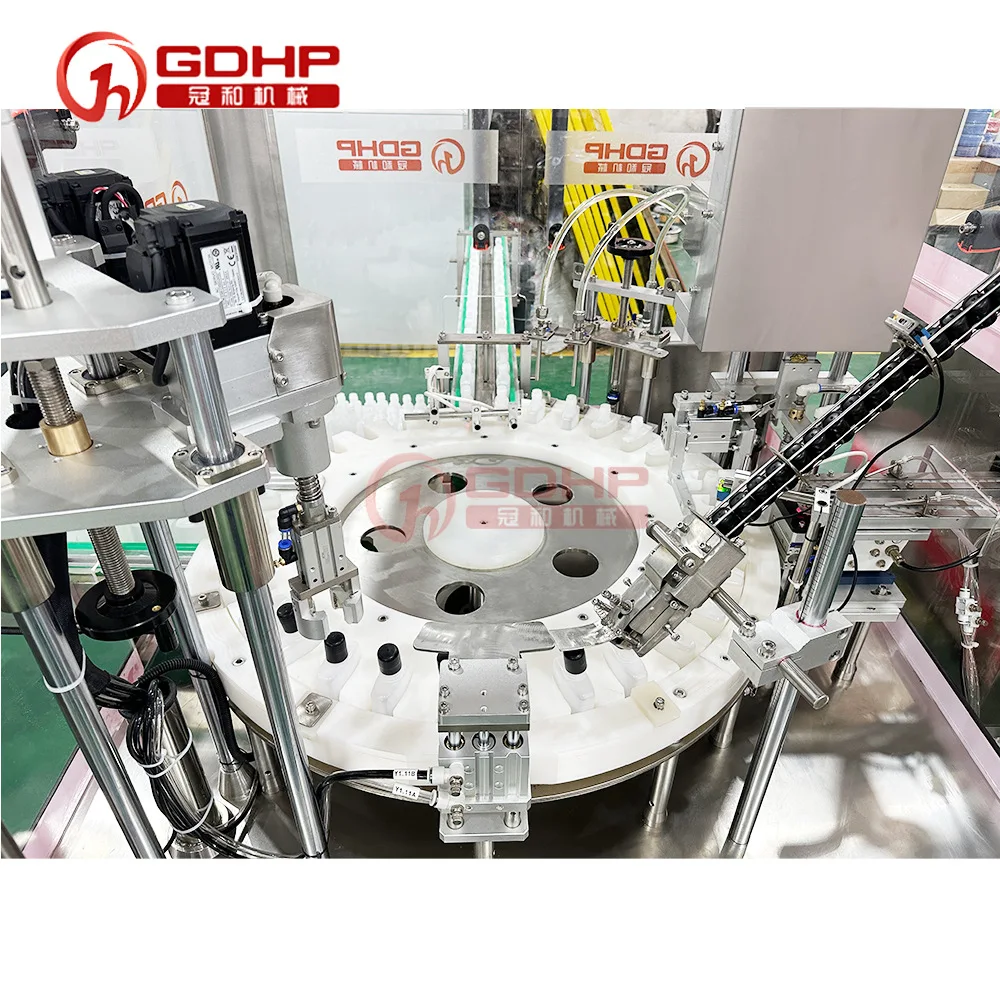

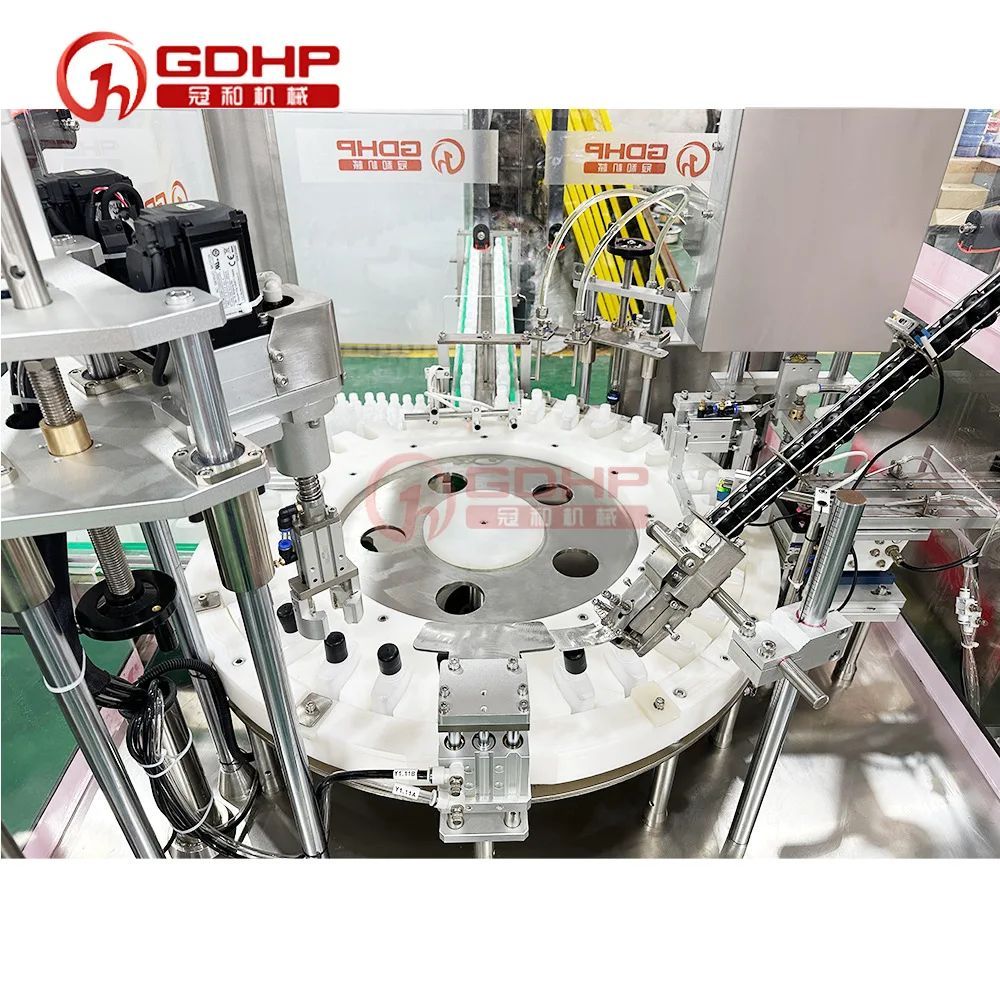

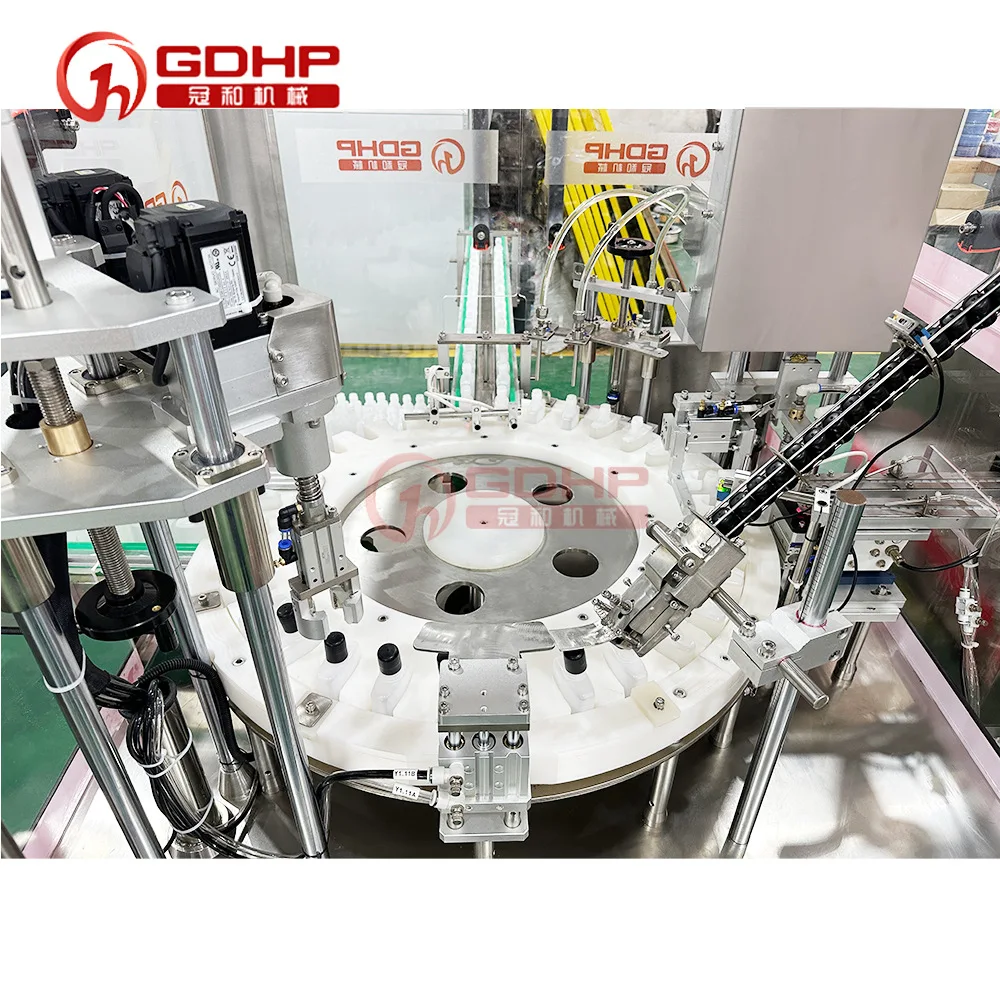

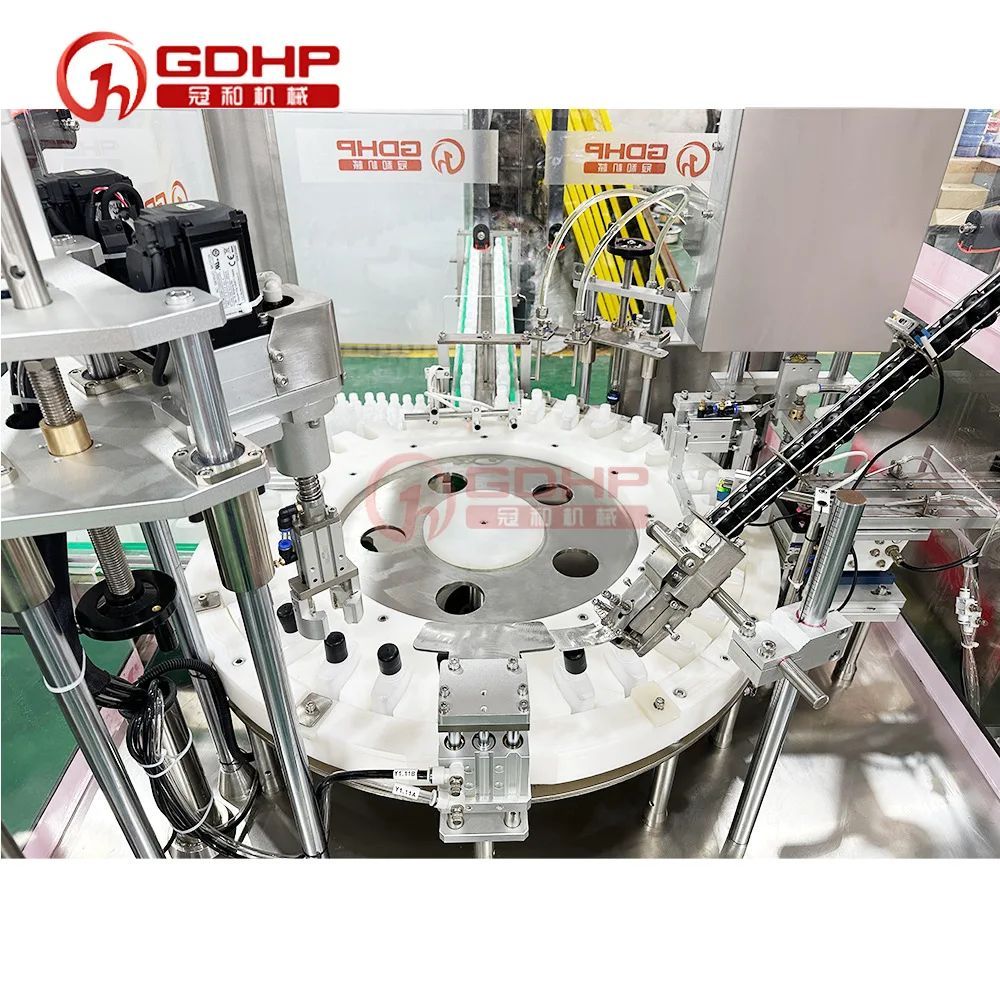

Customized Electric Rotary Automatic Body Lotion Filling Capping Machine Pneumatic All-in-One Solution for Glycerin Water

Designed for high-viscosity liquids such as glycerin.

Adopts high-precision metering system to ensure accurate filling and no dripping.

The equipment automatically completes operations such as capping, capping and capping.

Ensures reliable sealing, reduces manual contact, is simple to operate and easy to maintain, and is suitable for automated production in the pharmaceutical, daily chemical, chemical and other industries.

| Availability: | |

|---|---|

| Quantity: | |

-

GHYT-02

Equipment name: glycerin, moisturizing oil, moisturizing lotion, water cream skin care products automatic filling and capping machine

Process:

Manually place the bottles in the conveyor belt in the same direction double-track feeding detection double-head filling double-head plug taking and pressing automatic cap hanging automatic double-head servo capping double-track bottle discharging monorail conveying, the wholePLCControl, automatic completion of production.

This product isThe special equipment customized according to the bottle specifications provided by the buyer is mainly used for a specification of the assembly line. It is developed by the company's professional team, with reasonable structure and use effect, stable and durable quality. Provide good assistance for the demander to save labor costs and improve product quality and improve the company's operation automation. The machine uses PLC control, touch screen operation, high degree of automation. Advanced design and compact structure.

Bottle feeding method: manual bottle feeding to double-track conveyor belt, double row can accommodate30-40 bottles

Operation mode: double-station turntable intermittent

Filling method: usingSUS316 gear pump filling has a large filling adjustment range, high filling accuracy, simple filling volume and filling speed adjustment, which overcomes the troubles of slow traditional filling and small filling range from the root. Man-machine interface, parameter setting, convenient and quick calling of parameter groups, PLC programmable control, providing multiple groups of memory areas, schemes and memory storage functions to automatically store filling measurement; The filling of the same medium and measurement is directly called from the memory bank without adjusting the equipment again.

The way to manage the cover: the vibration plate is used to manage the cover, and the cover machine contains a sound insulation cover to reduce the noise of the equipment.

Plug-up mode : Using cam vacuum suction cup, it is directly sucked into the bottle, with accurate cap placement, full cam structure and accurate positioning.

The upper cover method adopts the screw cap head to grab the cap, directly grab the cap and put it into the bottle mouth, and the servo torque controls the screw cap.

Appearance: stainless steel304 material with plexiglass cover, durable and beautiful

Equipment name: glycerin, moisturizing oil, moisturizing lotion, water cream skin care products automatic filling and capping machine

Process:

Manually place the bottles in the conveyor belt in the same direction double-track feeding detection double-head filling double-head plug taking and pressing automatic cap hanging automatic double-head servo capping double-track bottle discharging monorail conveying, the wholePLCControl, automatic completion of production.

This product isThe special equipment customized according to the bottle specifications provided by the buyer is mainly used for a specification of the assembly line. It is developed by the company's professional team, with reasonable structure and use effect, stable and durable quality. Provide good assistance for the demander to save labor costs and improve product quality and improve the company's operation automation. The machine uses PLC control, touch screen operation, high degree of automation. Advanced design and compact structure.

Bottle feeding method: manual bottle feeding to double-track conveyor belt, double row can accommodate30-40 bottles

Operation mode: double-station turntable intermittent

Filling method: usingSUS316 gear pump filling has a large filling adjustment range, high filling accuracy, simple filling volume and filling speed adjustment, which overcomes the troubles of slow traditional filling and small filling range from the root. Man-machine interface, parameter setting, convenient and quick calling of parameter groups, PLC programmable control, providing multiple groups of memory areas, schemes and memory storage functions to automatically store filling measurement; The filling of the same medium and measurement is directly called from the memory bank without adjusting the equipment again.

The way to manage the cover: the vibration plate is used to manage the cover, and the cover machine contains a sound insulation cover to reduce the noise of the equipment.

Plug-up mode : Using cam vacuum suction cup, it is directly sucked into the bottle, with accurate cap placement, full cam structure and accurate positioning.

The upper cover method adopts the screw cap head to grab the cap, directly grab the cap and put it into the bottle mouth, and the servo torque controls the screw cap.

Appearance: stainless steel304 material with plexiglass cover, durable and beautiful