- Home

-

-

- Xilin bottle liquid vial filling machine vial machine, plugging and capping vial sealing machine

- Wind oil essence, activating oil, perfume small liquid filling machine filling line equipment

- filling roller bottle cold compress gel high speed filling machine

- Rhinitis nasal Spray bottle filling machine

-

-

- PET bottle juice filling machine juice bottling machine juice filling line

- Juice beverage filling machine capping packaging machine production line

- Oral liquid filling machine gas washing bottle filling line

- Pulp milk beverage bottle cleaning bottle high speed rotary fruit juice filling packing machine

-

-

- Dishwashing paste hot filling and cold pressing capping production line

- Perfume filling machine prices high speed plug capping production line

- Automatic bottling balm filling machine price and cooling small bottle filling machine

- Medicated disinfectant toner perfume spray digital liquid filling machine price bottling machine

-

-

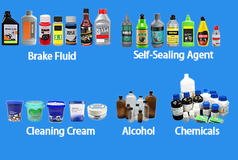

- Tire self-hydrating industrial bottle filling machine liquid filler

- Detergent Corrosion-resistant liquid filling machine industrial bottle filler

- Sterilization gel filling machine explosion-proof pharmaceutical liquid filling machine

- automatic 16 head ink filling cap screwing aluminum foil sealer ink filling machine

-

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Category

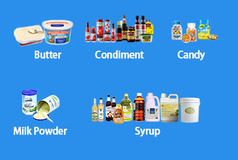

- Food machinery

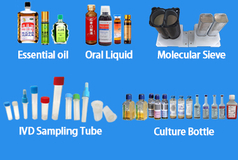

- Medical machinery

- Cosmetic machinery

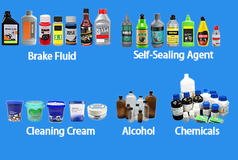

- Chemical machinery

- Beverage machinery

- Filling production line series

- Filling machine series

- Capping machine series

- Sealing machine series

- Label machine series

- Bottle unscrambler, bottle washing series

- Packing machine series

- Sachet packing machine series

- Accessories/Match machinery

News

- Wet Bottle Washing, Filling And Capping Production Line

Integrates automatic bottle washing, filling and capping.Bulk bottles are arranged in order and transported to each station through the automatic bottle sorting device.Multi-station spray bottle washing is used to rinse the bottle mouth, bottle body and bottle bottom in all directions.After washing,

- Body Lotion Glycerin Water All-In-One Automatic Rotary Filling Capping Machine

Integrates filling, capping and capping in one machine.Designed for high-viscosity liquids such as glycerin.Adopts high-precision metering system to ensure accurate filling and no dripping.The equipment automatically completes operations such as capping, capping and capping.Ensures reliable sealing,

- High-speed Bottle Washing, Filling, Capping And Labeling Production Line

High-speed bottle washing, filling, capping and labeling production line Through ultrasonic vibration and spraying double cleaning, effectively removing internal and external impurities and dust, followed by high-temperature tunnel to complete the drying and aseptic treatment, adopts the plunger pum

- Dishwashing Cream Hot Filling, Cooling, Pressing And Packing Production Line

Adopting precise temperature control system to ensure smooth and even filling without collapsing.Efficient cooling and plug-pressing linkage system ensures the paste to be quickly characterized without deformation.Automatic carton loading saves time and labor, realizing the whole process automation

- Cooling oil Filling And Capping Integrated Machine

Capable of achieving continuous filling and capping operations. Without the need for frequent manual interventionReduces downtime in production. While possessing a high operating speed. Can complete the filling and capping of a large number of products in a short period of timeMeets the demands of rapid

Automated Essence filling machine for sale, plugging and capping all-in-one machine

| Availability: | |

|---|---|

| Quantity: | |

-

GDHP

Overview:

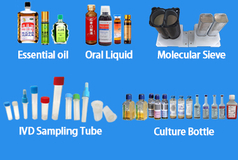

This model is specially designed by our company for small-dose bottles. It is suitable for the automatic equipment of bottle feeding, filling, plugging and capping of automatic bottles for liquid materials.

Features:

1. High-precision peristaltic pump is used for filling, PLC setting controls the measurement, and the filling volume and the number of filling bottles can be set through the touch screen on the equipment. The filling adjustment range is large, the precision is high, and the operation is convenient; this system can automatically fill, and automatically lower the cover and screw the cap. It is a high-tech filling equipment integrating machinery and electricity. and replacement, saving time and effort.

2. This equipment is specially designed for small-dose liquid filling and sealing in cosmetics and pharmaceutical industries (this equipment is suitable for two bottle shapes provided by the buyer) and is suitable for different diameters and heights of 1-10ml (stoppers and caps need to be consistent ), you don’t need to adjust any other mechanical parts of the equipment when changing the bottle type, you only need to set the filling volume on the touch screen.

3. The filling station adopts high-precision peristaltic pump for metering, which is convenient for cleaning and disinfection, and can quickly switch between filling different liquid materials.

4. The stopper and cover are all discharged by vibrating plate, and the arranged stopper and cover are put into the bottle mouth by rotating the manipulator.

5. The mold is adopted for easy-to-invert bottle shapes and different bottle shapes, combined with the circular conveyor belt, the operation is stable, safe, and manual operation is simple.

6. The integrated design not only ensures the accuracy and speed of filling and capping, but also occupies a small area and has a beautiful appearance, which fully meets the requirements of GMP. Widely used for filling and capping small bottles of food, pharmaceuticals, daily chemicals, etc., this system is specially customized according to the bottle type of the customer.

Technical Parameters:

| Model | GHAFC-2-2-2 | Filling range | 1-10ml Two bottle shapes provided by the buyer |

| Filling head | double head | Press plug, screw cap | double head |

| Filling and capping speed | More than 40 bottles/min (1-10ML) | Loading accuracy | 2% |

| Capping pass rate | ≥99% | speed control | Variable frequency speed regulation |

| Rated power | 1.2kw | Operating Voltage | 220V 50HZ |

| Working pressure | 0.4-0.6Mpa | Stand-alone noise | ≤70dB |

| Equipment Approximate Weight | 600kg | Dimensions | About 2000*1800*1600mm |

FAQ:

Q:Are you a manufacturer or trade company?

A:We are a manufacturer in filling and packing machine field more than 20 years, located at Huadu district, Guangzhou city, which is nearby Baiyun Airport.

Q:Do you have any certification?

A:ISO9001,CE

Q:What about the delivery time?

A:Usually 30-60 Working days

Q:What about the machine's capacity?

A:it depended on your production capacity requirement

Q:The after-sale service

A:12 months warranty.

solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machine or by email.

Q: If I want to buy a machine, what information do I need to tell you, do you need from me?

A: a. What kind liquid/cream/powder/particles you want to produce?

b. bottle/sachet volume? 3ml, 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d.Raw material picture or video

e.Voltage and altitude.

Q:What kinds of product you supply?

A: Food, cosmetic, pharmaceutical, daily chemicals filling line.

After packing system(label machine, PE film shrink packing machine, carton machine etc)

Overview:

This model is specially designed by our company for small-dose bottles. It is suitable for the automatic equipment of bottle feeding, filling, plugging and capping of automatic bottles for liquid materials.

Features:

1. High-precision peristaltic pump is used for filling, PLC setting controls the measurement, and the filling volume and the number of filling bottles can be set through the touch screen on the equipment. The filling adjustment range is large, the precision is high, and the operation is convenient; this system can automatically fill, and automatically lower the cover and screw the cap. It is a high-tech filling equipment integrating machinery and electricity. and replacement, saving time and effort.

2. This equipment is specially designed for small-dose liquid filling and sealing in cosmetics and pharmaceutical industries (this equipment is suitable for two bottle shapes provided by the buyer) and is suitable for different diameters and heights of 1-10ml (stoppers and caps need to be consistent ), you don’t need to adjust any other mechanical parts of the equipment when changing the bottle type, you only need to set the filling volume on the touch screen.

3. The filling station adopts high-precision peristaltic pump for metering, which is convenient for cleaning and disinfection, and can quickly switch between filling different liquid materials.

4. The stopper and cover are all discharged by vibrating plate, and the arranged stopper and cover are put into the bottle mouth by rotating the manipulator.

5. The mold is adopted for easy-to-invert bottle shapes and different bottle shapes, combined with the circular conveyor belt, the operation is stable, safe, and manual operation is simple.

6. The integrated design not only ensures the accuracy and speed of filling and capping, but also occupies a small area and has a beautiful appearance, which fully meets the requirements of GMP. Widely used for filling and capping small bottles of food, pharmaceuticals, daily chemicals, etc., this system is specially customized according to the bottle type of the customer.

Technical Parameters:

| Model | GHAFC-2-2-2 | Filling range | 1-10ml Two bottle shapes provided by the buyer |

| Filling head | double head | Press plug, screw cap | double head |

| Filling and capping speed | More than 40 bottles/min (1-10ML) | Loading accuracy | 2% |

| Capping pass rate | ≥99% | speed control | Variable frequency speed regulation |

| Rated power | 1.2kw | Operating Voltage | 220V 50HZ |

| Working pressure | 0.4-0.6Mpa | Stand-alone noise | ≤70dB |

| Equipment Approximate Weight | 600kg | Dimensions | About 2000*1800*1600mm |

FAQ:

Q:Are you a manufacturer or trade company?

A:We are a manufacturer in filling and packing machine field more than 20 years, located at Huadu district, Guangzhou city, which is nearby Baiyun Airport.

Q:Do you have any certification?

A:ISO9001,CE

Q:What about the delivery time?

A:Usually 30-60 Working days

Q:What about the machine's capacity?

A:it depended on your production capacity requirement

Q:The after-sale service

A:12 months warranty.

solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machine or by email.

Q: If I want to buy a machine, what information do I need to tell you, do you need from me?

A: a. What kind liquid/cream/powder/particles you want to produce?

b. bottle/sachet volume? 3ml, 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d.Raw material picture or video

e.Voltage and altitude.

Q:What kinds of product you supply?

A: Food, cosmetic, pharmaceutical, daily chemicals filling line.

After packing system(label machine, PE film shrink packing machine, carton machine etc)